Counterweight assemblies are foundational to many modern machines, especially in fitness equipment, industrial tools, aerospace systems, and robotics. From the stability of your home gym’s weight rack to the balance of a high-performance aircraft engine, counterweights play a crucial role in ensuring safety, performance, and longevity. In this blog, we’ll break down what counterweight assemblies are, why they matter, and how they’re shaping innovation in various industries.

I. What Are Counterweight Assemblies?

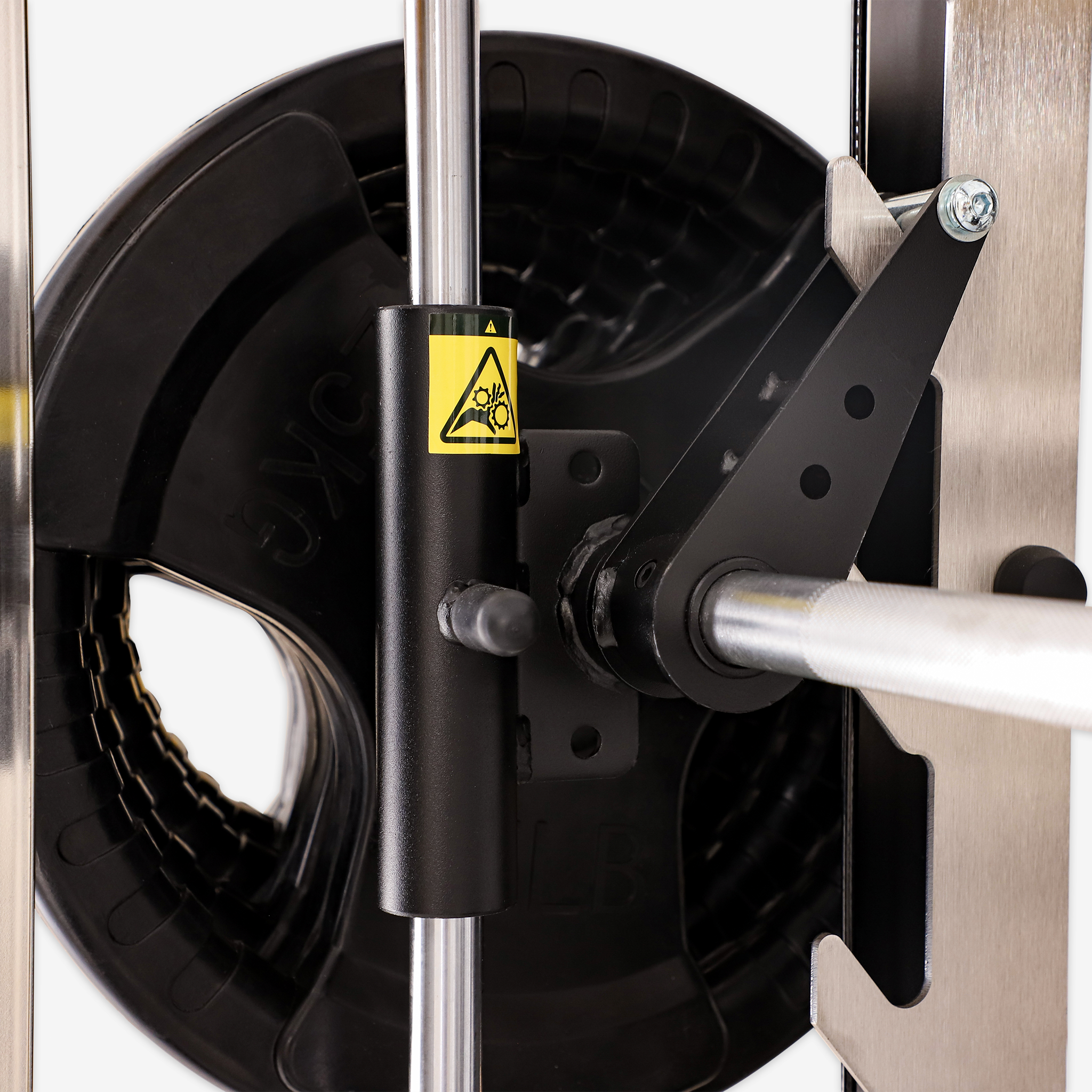

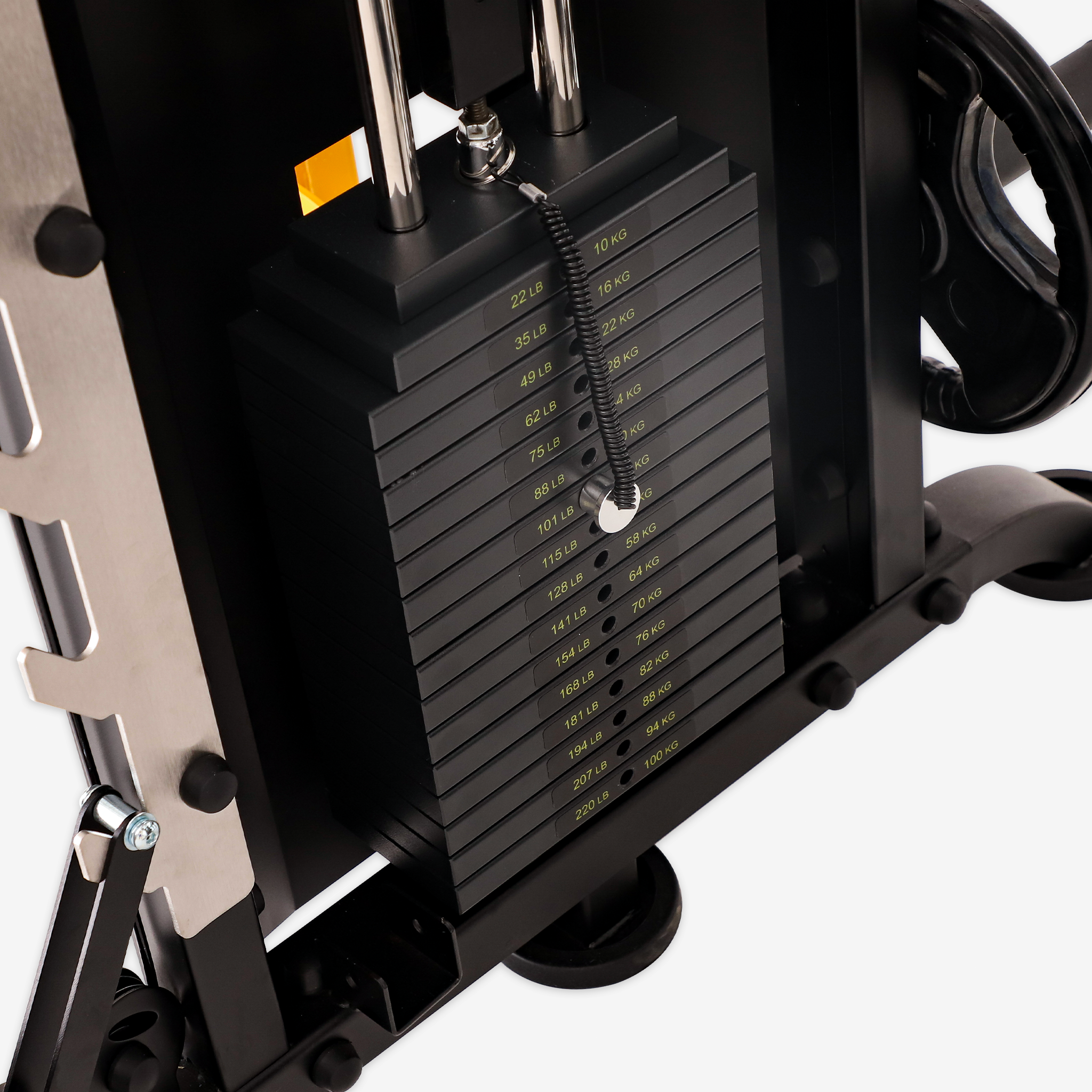

A counterweight assembly is a system of components—typically including weights, frames, and connecting mechanisms—designed to balance and stabilize a machine during operation. Whether you're lifting weights or flying at 30,000 feet, these assemblies keep motion smooth and vibrations low.

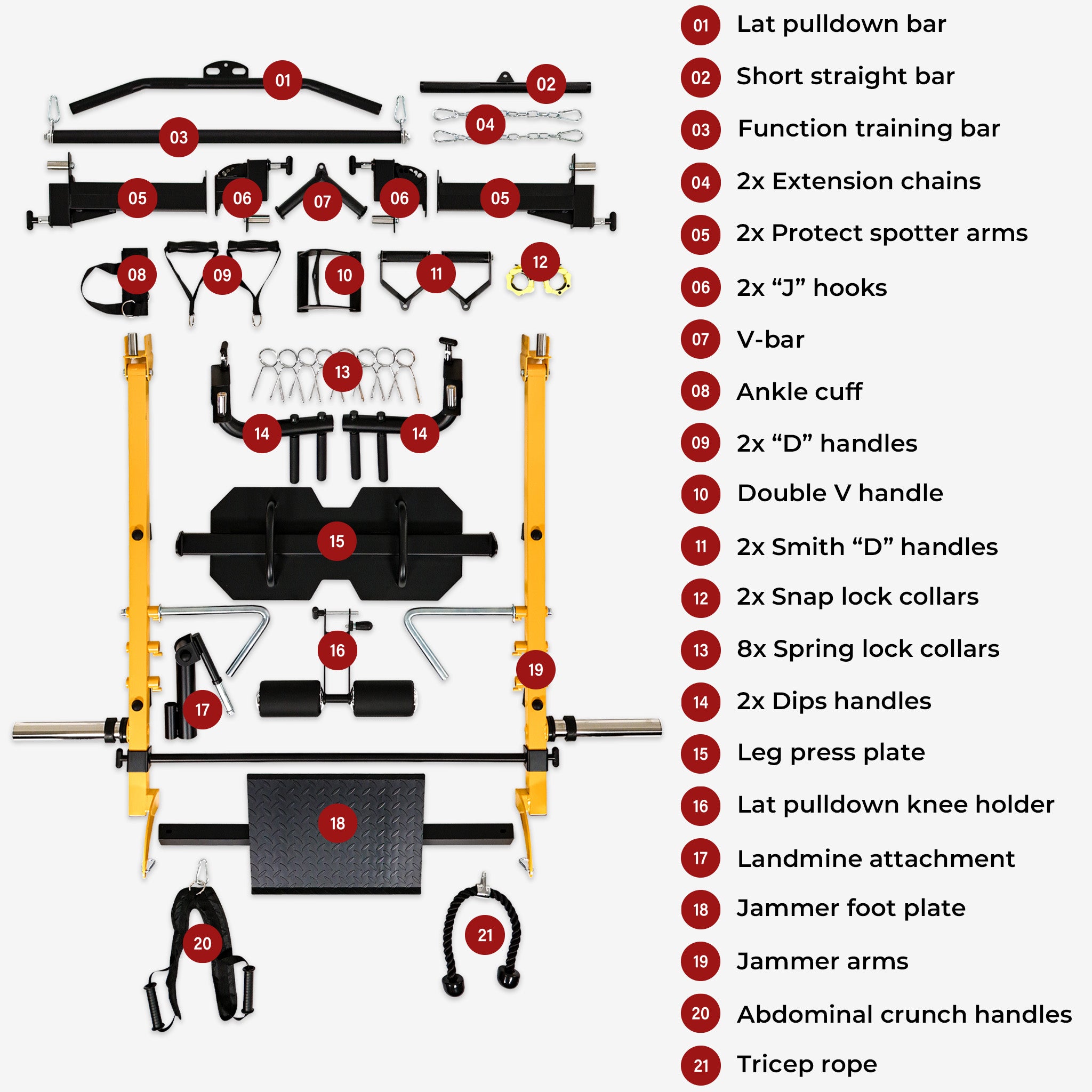

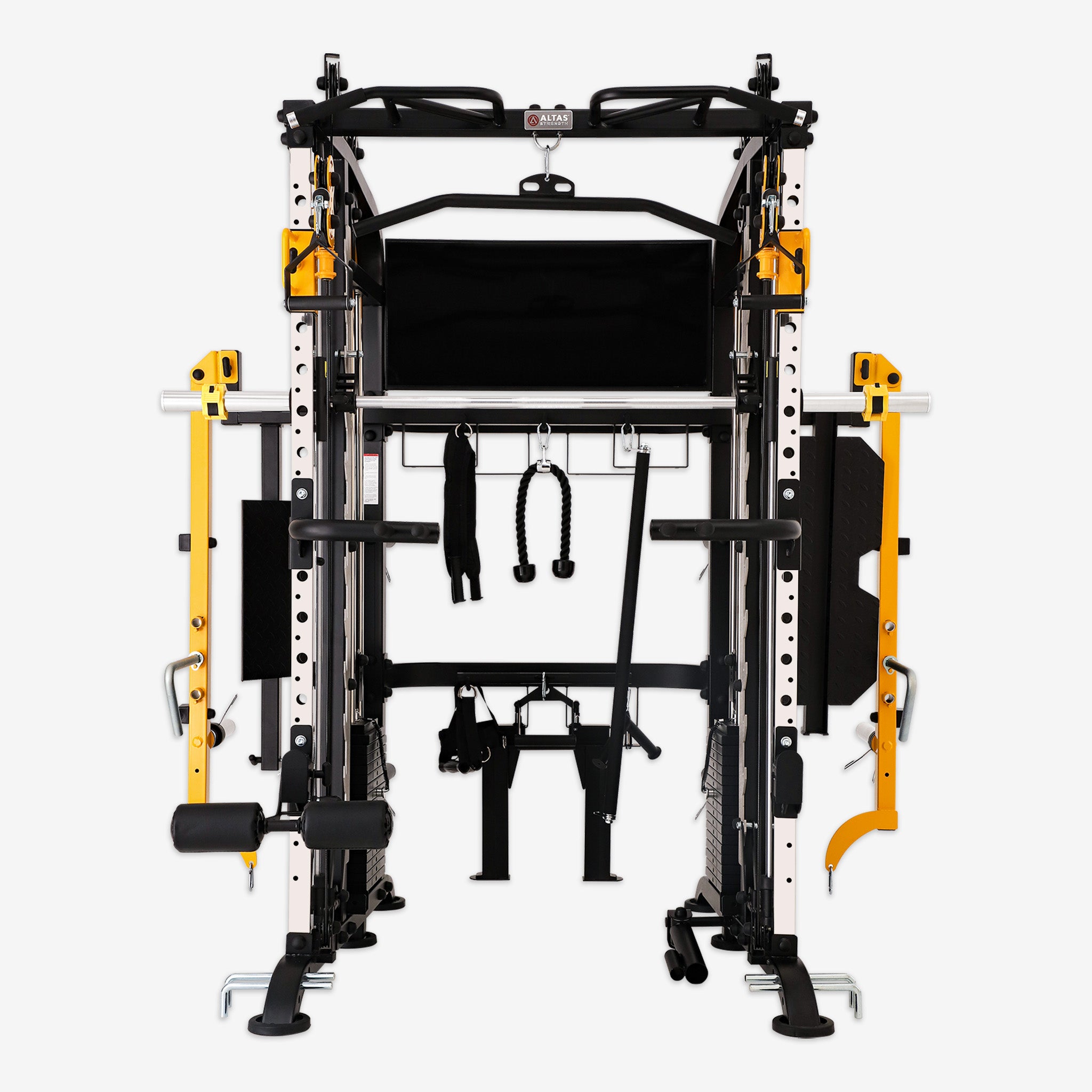

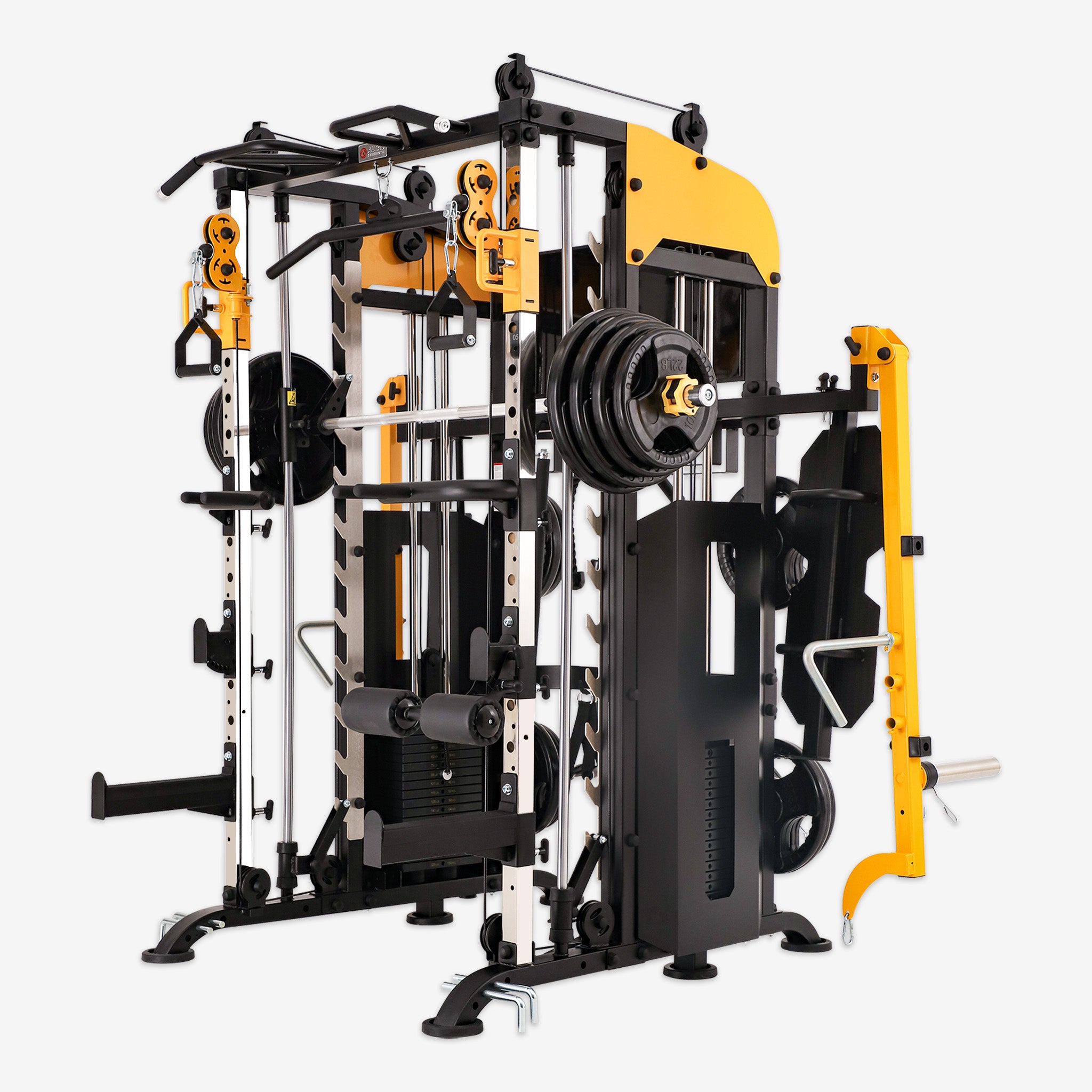

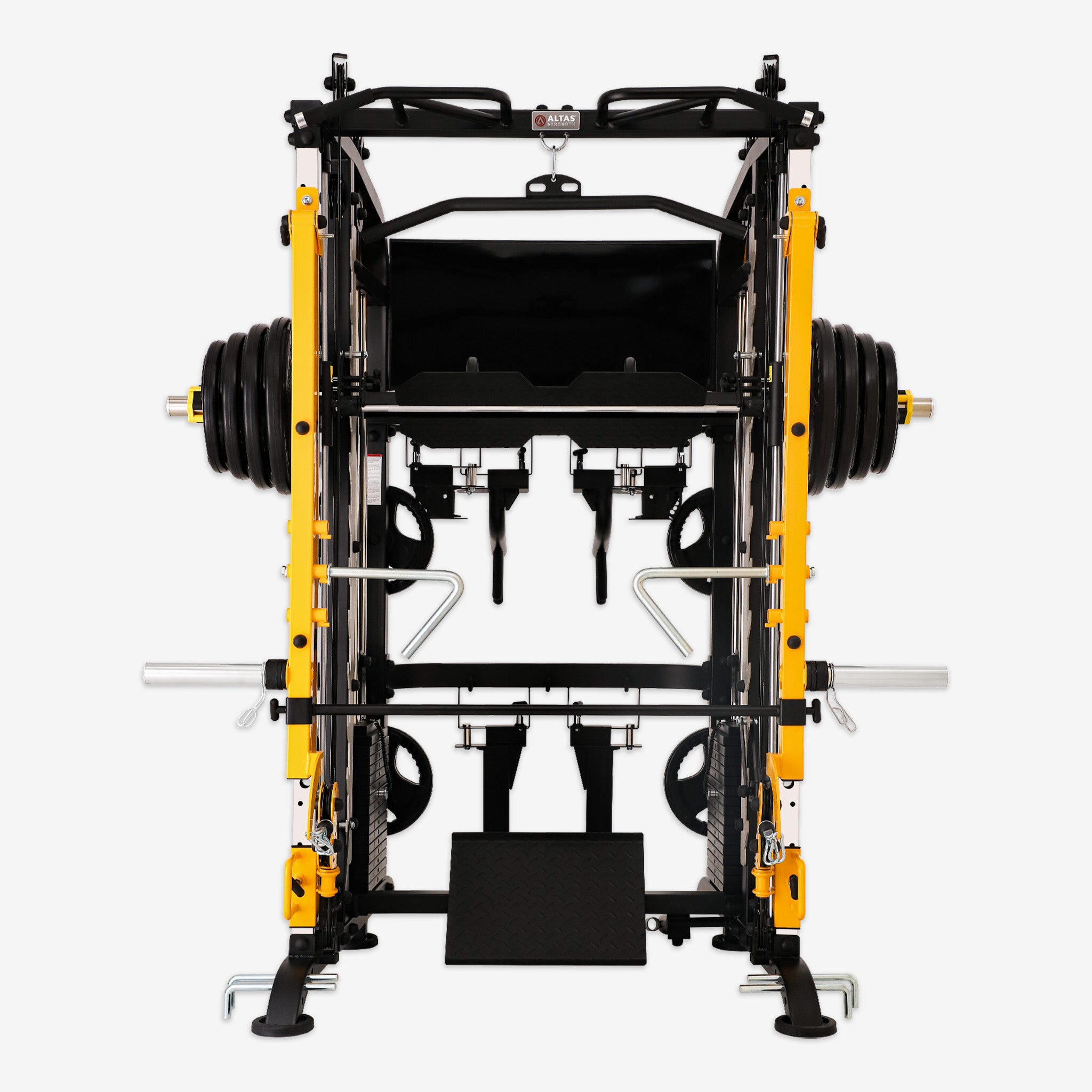

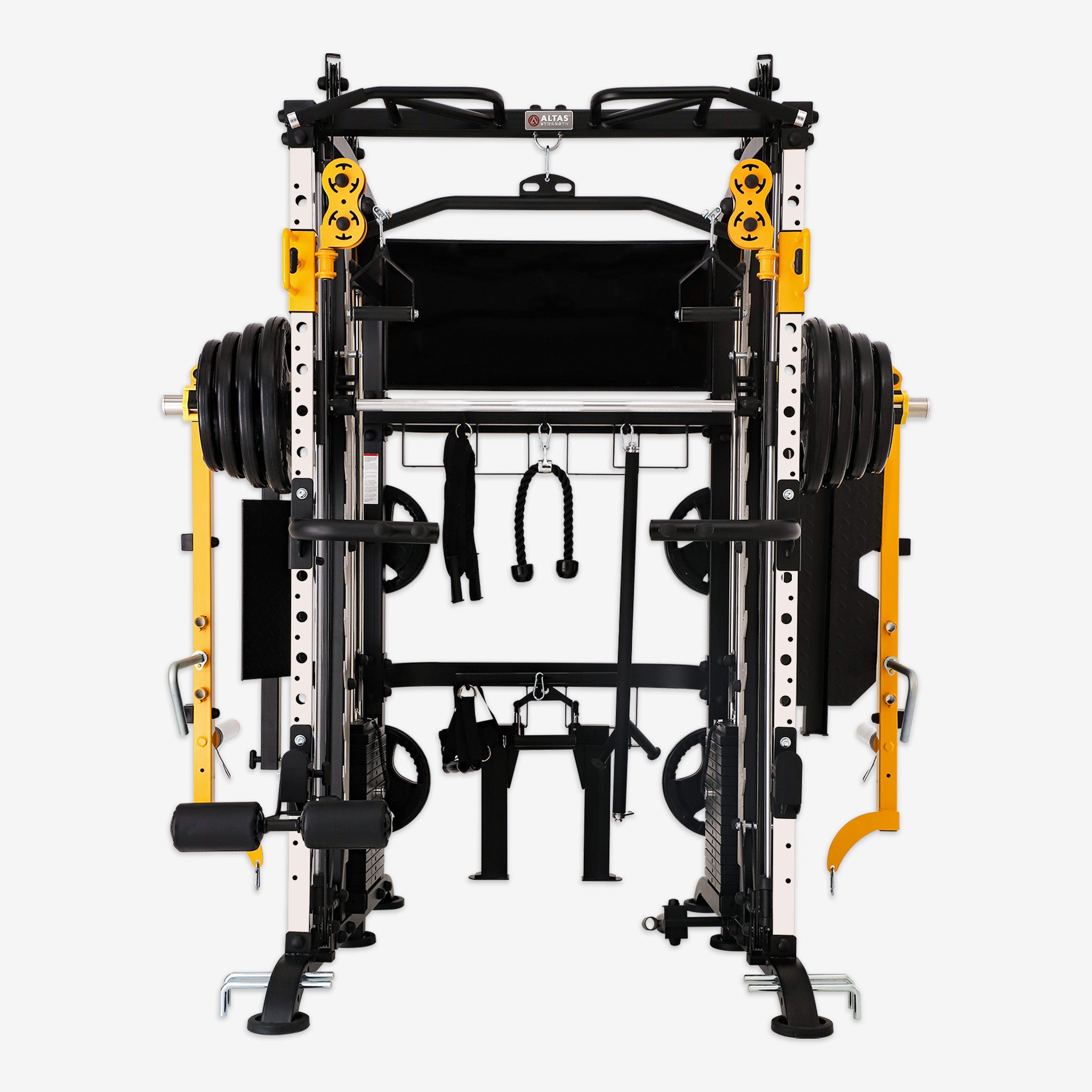

For example, in a lat pulldown machine or squat rack, the counterweight stack ensures stable resistance, enabling safe, controlled movements. In aviation, they dampen engine vibration, which can prevent wear and extend lifespan.

II. Key Design Principles

1. Balance and Stability

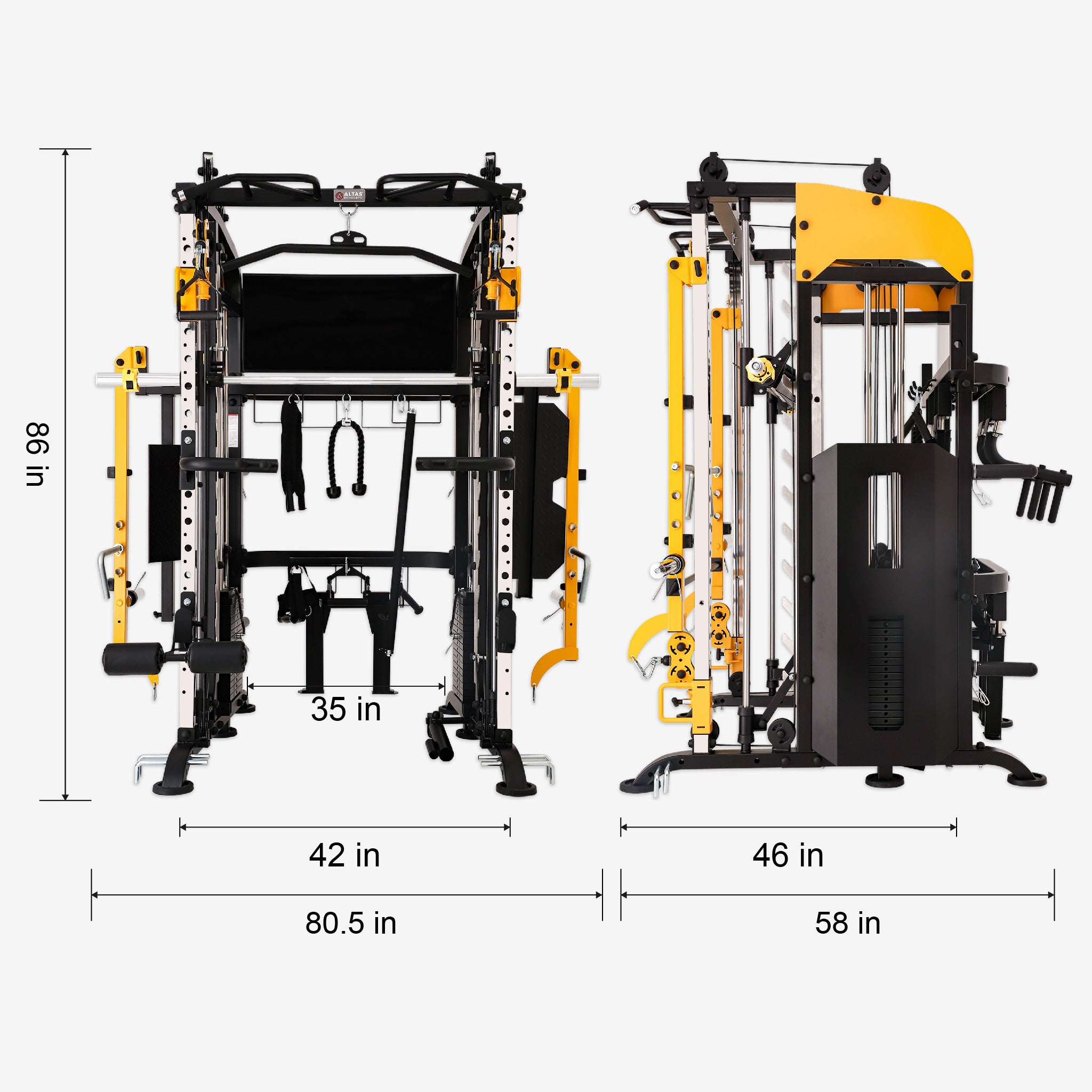

Good counterweight assemblies reduce tipping and unwanted motion. In fitness machines, this means safer reps and better alignment. In cranes or elevators, it reduces risk and increases load capacity.

2. Intelligent Material Use

Tungsten, cast iron, and durable alloys are commonly used based on the machine’s purpose. In piston aircraft engines, tungsten is placed strategically to offset torque and maintain flight stability.

3. Dynamic Adjustability

Modern systems—like robotic arms or smart washing machines—allow for real-time adjustment. This means they shift their center of gravity based on the load, improving performance and safety.

III. Where You’ll Find Counterweight Assemblies

🏋️♂️ Fitness Equipment

Home gyms often use counterweight stacks in Smith machines or lat pulldown systems, making strength training more controlled and effective.

✈️ Aerospace

Aircraft engines rely on counterweights to eliminate destructive vibration during high-speed flight.

🏗️ Cranes & Industrial Machinery

Used for lifting stability, preventing tip-overs, and supporting dynamic movement of heavy loads.

🤖 Robotics

In robotics, counterweight placement improves precision and balance, especially during high-speed or delicate movements.

🧺 Home Appliances

Washing machines feature fluid-filled counterweights to reduce noise and vibration during spin cycles.

IV. The Future of Counterweight Assemblies

With growing demand for efficiency and safety, counterweight technology is evolving in exciting ways:

-

AI and Sensor Integration: Smarter machines will adjust counterweight balance on the fly.

-

Eco-Friendly Materials: Recyclable or low-carbon components will reduce environmental impact.

-

Cost-Effective Design: As production scales, prices will fall—making smart fitness equipment and machinery more accessible.

V. Conclusion

Whether you're investing in a home gym weight rack or managing heavy-duty equipment, counterweight assemblies are the hidden heroes of mechanical design. They ensure stability, safety, and performance—and their importance will only grow as technology advances.

Looking to upgrade your fitness setup or understand your equipment better? Recognizing the value of a well-designed counterweight assembly is a step toward safer and smarter training.