In modern industry, logistics, and even daily operations, moving heavy objects efficiently and safely is a constant challenge. A weight pulley system is a simple yet powerful solution that reduces physical effort, increases work speed, and minimizes the risk of injury.

Whether used in warehouses, construction sites, production lines, or workshops, pulley systems provide mechanical advantages that make lifting and transporting loads easier, faster, and safer.

I. Reduce Physical Effort with Mechanical Advantage

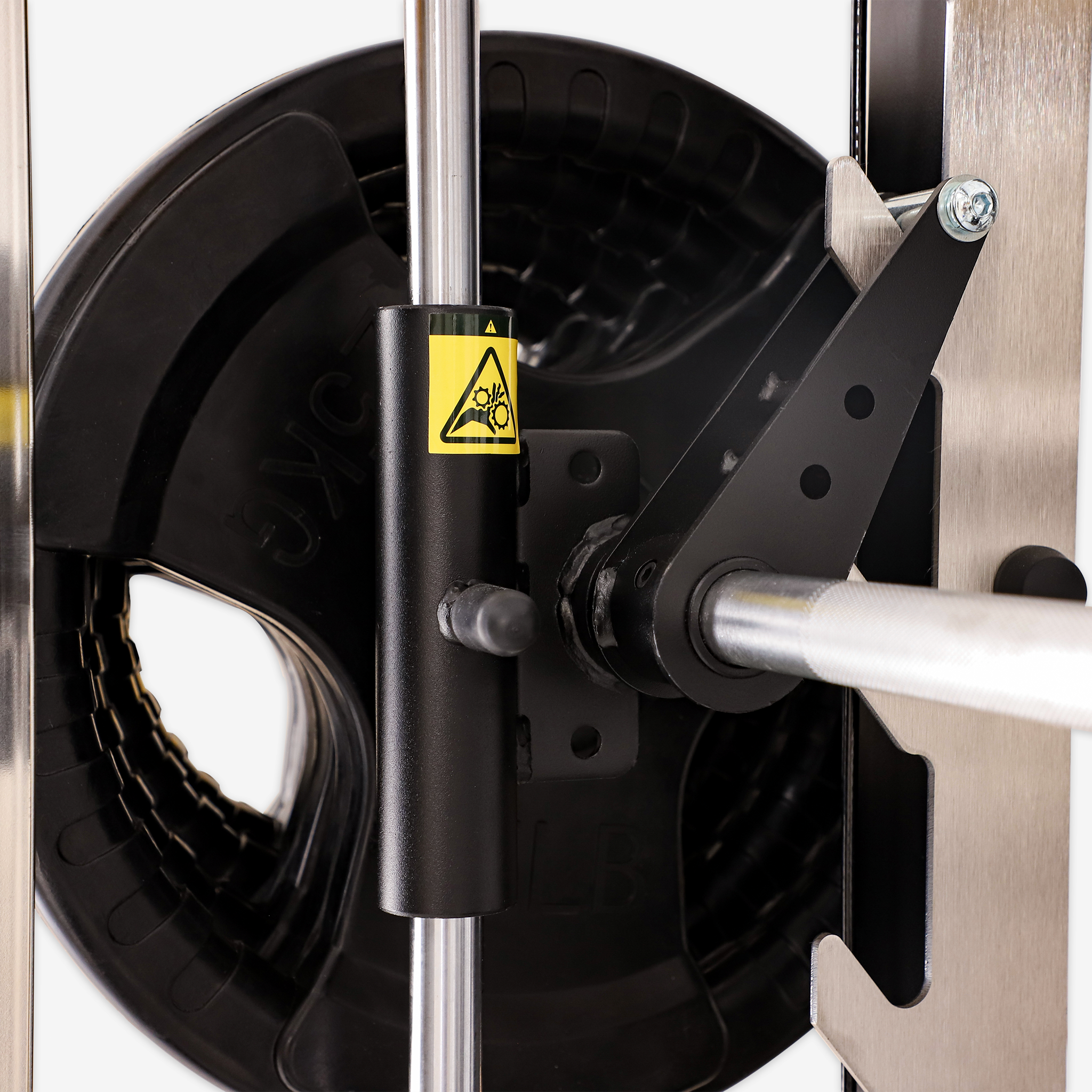

Pulleys work by changing the direction of applied force and distributing it across multiple points.

-

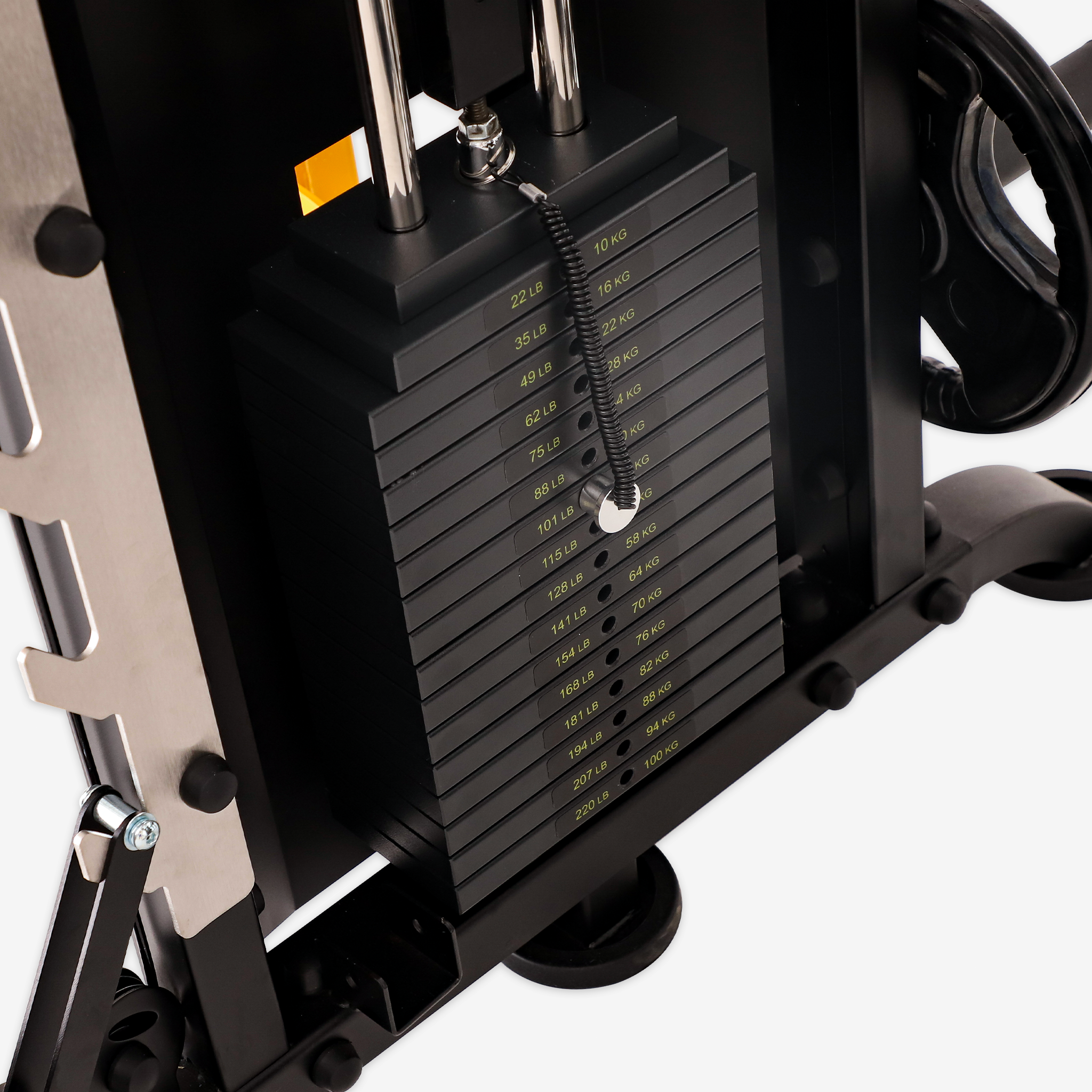

A single movable pulley can halve the effort required to lift a load.

-

Compound pulley systems can reduce the input force to a quarter or less.

This labor-saving feature allows workers to lift heavy objects without excessive strain, improving efficiency and reducing fatigue.

Example: Lifting a 100 kg load using a compound pulley system may only require 25 kg of force, making heavy lifting manageable for one person.

II. Enhance Work Efficiency and Speed

With reduced effort, tasks can be completed faster and more consistently:

-

Faster lifting and moving in production lines and warehouses

-

Quicker setup due to simple construction and minimal installation time

-

Improved workflow efficiency, especially in environments with frequent lifting requirements

By combining multiple pulleys, operators can maintain a steady pace without tiring, boosting productivity.

III. Improve Safety and Reduce Injury Risk

Manual lifting often causes back injuries and musculoskeletal strain due to improper posture. Pulley systems address this by:

-

Allowing operators to pull from standing positions or ergonomic angles

-

Distributing load stress across multiple points, reducing single-point tension

-

Preventing sudden load drops with well-designed pulley ropes and supports

This makes pulley systems ideal for repetitive heavy lifting tasks where worker safety is paramount.

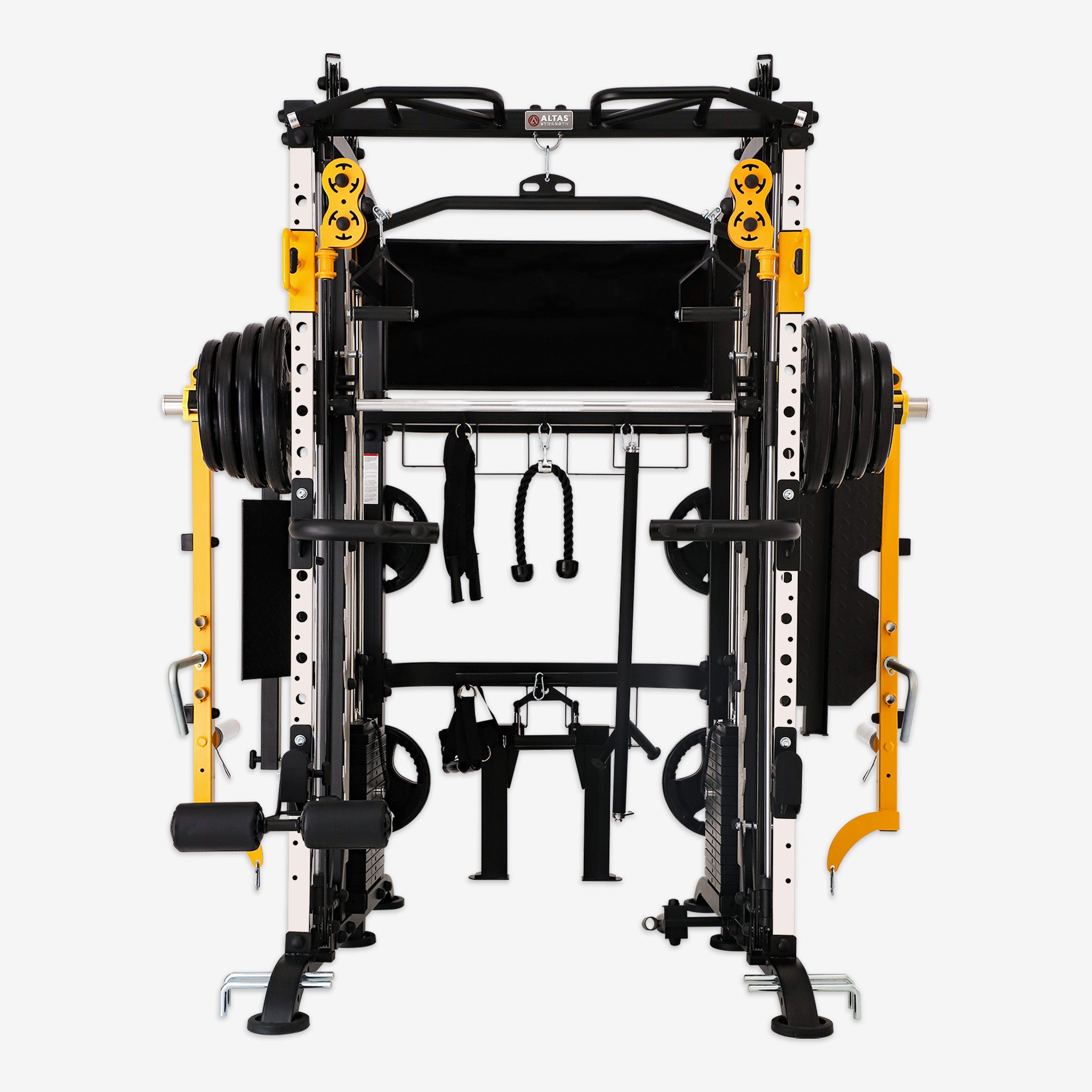

IV. Flexible Space Utilization

Pulley systems are compact and modular, making them suitable for limited spaces:

-

Easy installation in narrow workshops, warehouses, or high shelves

-

Gravity-based conveyors can transport materials without steep inclines

-

Adaptable layouts allow customized setups to optimize workflow

Whether space is tight or layouts are complex, pulley systems provide efficient material handling without sacrificing safety.

V. Low Cost and Minimal Maintenance

Compared to electric hoists or hydraulic lifts, pulley systems are affordable and simple to maintain:

-

Composed mainly of metal wheels, ropes, and belts

-

Maintenance involves lubricating axles and checking rope integrity

-

No complex electrical or hydraulic systems required

This makes pulley systems accessible to small and medium-sized enterprises, reducing overall operational costs while offering long-term reliability.

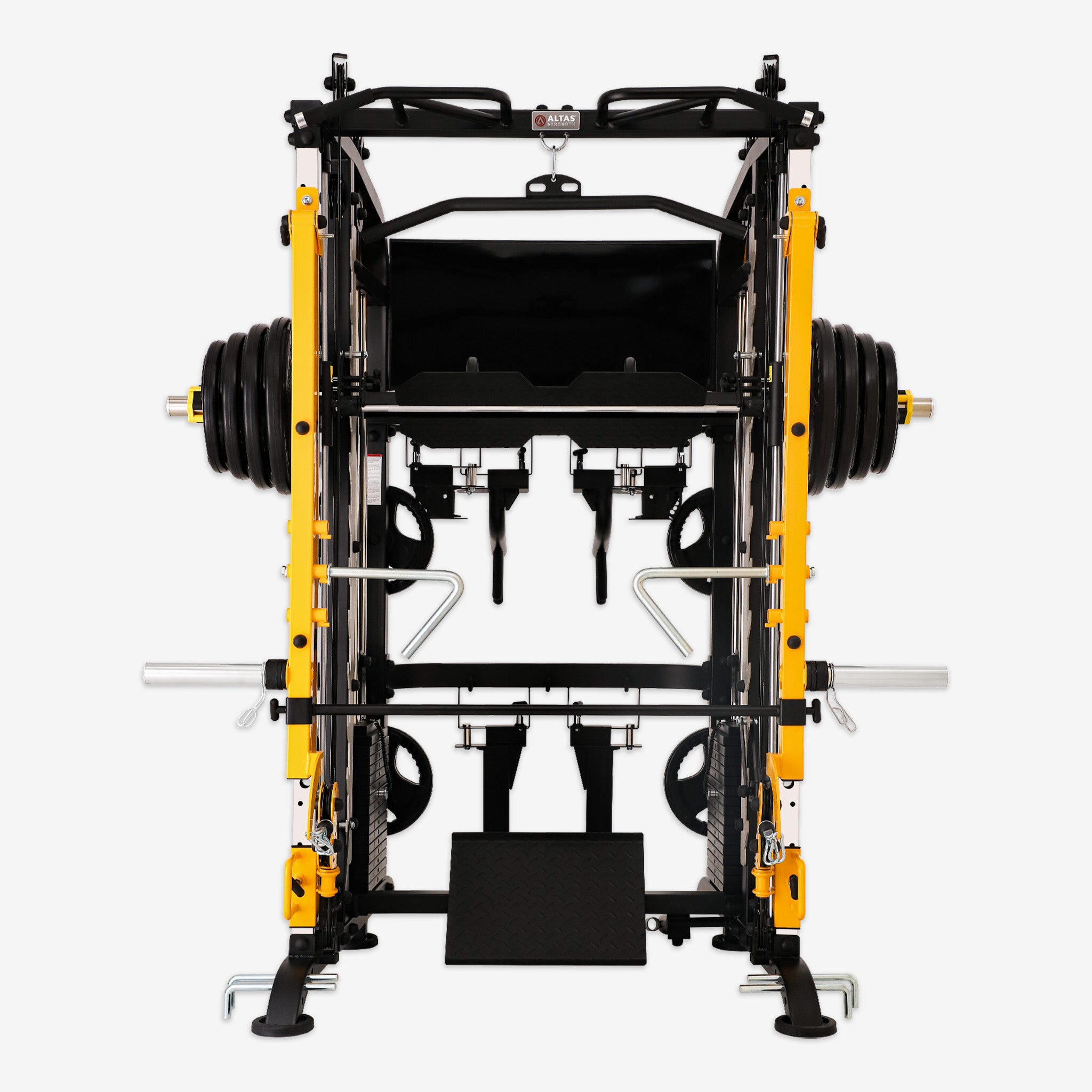

VI. Integration with Automated Systems

Modern pulley systems can easily integrate with automation solutions:

-

Combine with conveyors, robotic arms, or PLC systems for semi-automated or fully automated material handling

-

Increase load capacity without additional manpower

-

Enhance flexibility in industrial setups, from light assembly lines to heavy logistics

This adaptability allows businesses to upgrade from manual to automated systems seamlessly.

VII. Broad Applications Across Industries

Pulley systems are universally applicable, supporting a wide range of industries and tasks:

-

Construction sites: lifting building materials safely

-

Warehouses: moving pallets and inventory efficiently

-

Theater rigging: precise adjustment of stage scenery

-

Laboratories: handling delicate or heavy equipment

Their versatility eliminates the need for industry-specific lifting devices, making them a practical choice for multiple applications.

Conclusion

The weight pulley system is a labor-saving, efficient, safe, and cost-effective solution for lifting and moving heavy loads. By reducing physical effort, enhancing work speed, and improving safety, pulley systems provide long-term value with minimal investment.

Whether for a small workshop, large warehouse, or specialized industrial application, these systems make heavy lifting safer, faster, and more efficient, cementing their role as a critical tool in modern industry.

Invest in a weight pulley system today to maximize efficiency, safety, and productivity in your operations.